Ben’s Pizzeria

Table of Contents

- Objective

- Data Source

- Project Stages

- Design

- Development

- Testing

- Visualization

- Analysis

- Recommendations

- Implementation Plan

Objective

Create a comprehensive data management and analytics system for Ben’s Pizzeria to optimize operations and drive business decisions through:

- Building a normalized SQL database to manage orders, inventory, and staff data

- Creating interactive dashboards to visualize key business metrics

- Implementing data-driven insights for inventory management and staff scheduling

- Analyzing sales patterns and customer behavior to improve business operations

Key Areas of Focus

- Order Management & Sales Analysis

- Inventory & Stock Control

- Staff Scheduling & Cost Management

Data Source

Data is sourced from learnbi.online/pizzaproject providing information on:

- Menu items and pricing

- Ingredient costs and inventory

- Order details and history

- Staff information and schedules

- Customer data

Project Stages

- Design

- Development

- Analysis

- Recommendations

Design

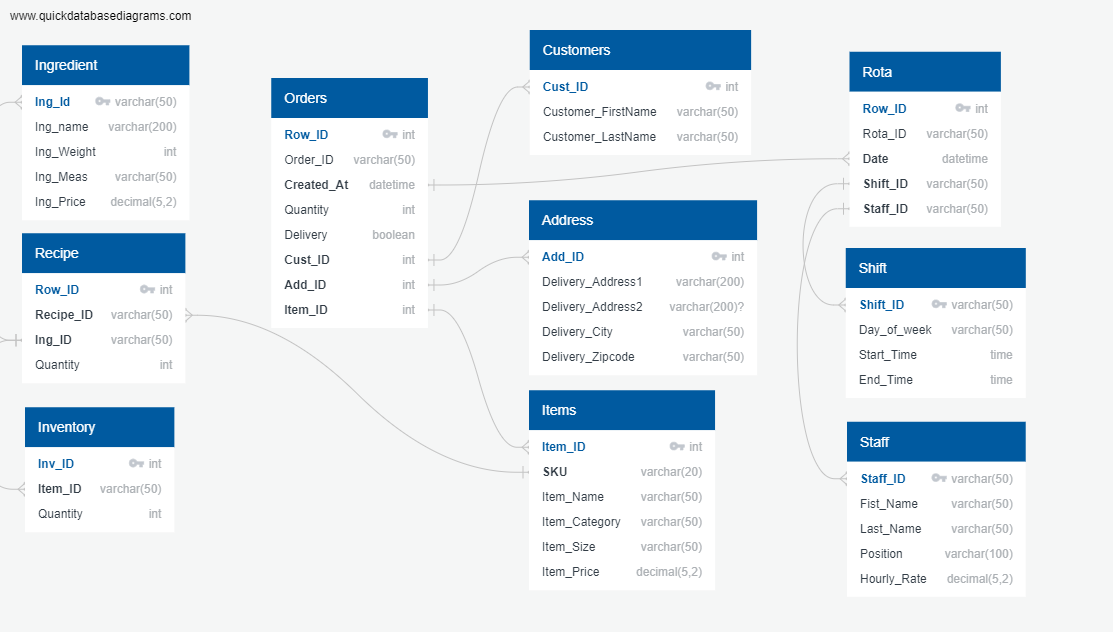

Database Design

Dashboard Components Required

Orders Management

- Order ID, Item Name, Price, Quantity

- Customer Information

- Delivery Details

- Product Categories

Stock Control

- Ingredients Inventory

- Recipe Requirements

- Stock Levels

Staff Management

- Employee Information

- Shift Schedules

- Labor Costs

Tools Used

| Tool | Purpose |

|---|---|

| Excel | Initial data exploration |

| SQL Server | Database creation and analysis |

| Power BI | Interactive dashboard creation |

| GitHub | Project documentation |

| QuickDBD | Database schema design |

Development

Database Structure

Orders Table

Row_ID int PK

Order_ID varchar(50)

Created_At datetime FK

Quantity int

Delivery boolean

Cust_ID int FK

Add_ID int FK

Item_ID int FK

[Additional table structures omitted for brevity]

SQL Views Created

Order Activity View

CREATE VIEW Order_activity AS

SELECT

orders.order_id,

items.Item_Price,

orders.Quantity,

items.Item_Category,

items.Item_Name,

orders.Created_At,

address.Delivery_Address1,

address.Delivery_Address2,

address.Delivery_City,

address.Delivery_Zipcode,

orders.Delivery

FROM Orders

LEFT JOIN items ON Orders.Item_ID = items.Item_ID

LEFT JOIN address ON Orders.Add_ID = address.Add_ID

Inventory Management View

CREATE VIEW Stock1 AS

SELECT

S1.Ing_name,

S1.Ing_Id,

S1.Ing_Weight,

S1.Ing_Price,

S1.item_name,

S1.order_quantity,

S1.recipe_quantity,

S1.order_quantity * S1.recipe_quantity as Ordered_weight,

S1.Ing_Price/s1.Ing_Weight as unit_cost,

(S1.order_quantity * S1.recipe_quantity) * (S1.Ing_Price/s1.Ing_Weight) as ingredient_cost

FROM [subquery omitted for brevity]

Staff Cost View

CREATE VIEW Staff_cost AS

SELECT

rota.Date,

staff.First_Name,

staff.Last_Name,

staff.Hourly_Rate,

shift.Start_Time,

shift.End_Time,

((HOUR(TIMEDIFF(shift.end_time,shift.start_time))*60) +

(MINUTE(TIMEDIFF(shift.end_time,shift.start_time))))/60 as hours_in_shift,

[calculated staff cost column] as staff_cost

FROM rota

LEFT JOIN staff ON rota.Staff_ID = staff.Staff_ID

LEFT JOIN shift ON rota.Shift_ID = shift.Shift_ID

Visualization

Interactive Dashboards Created

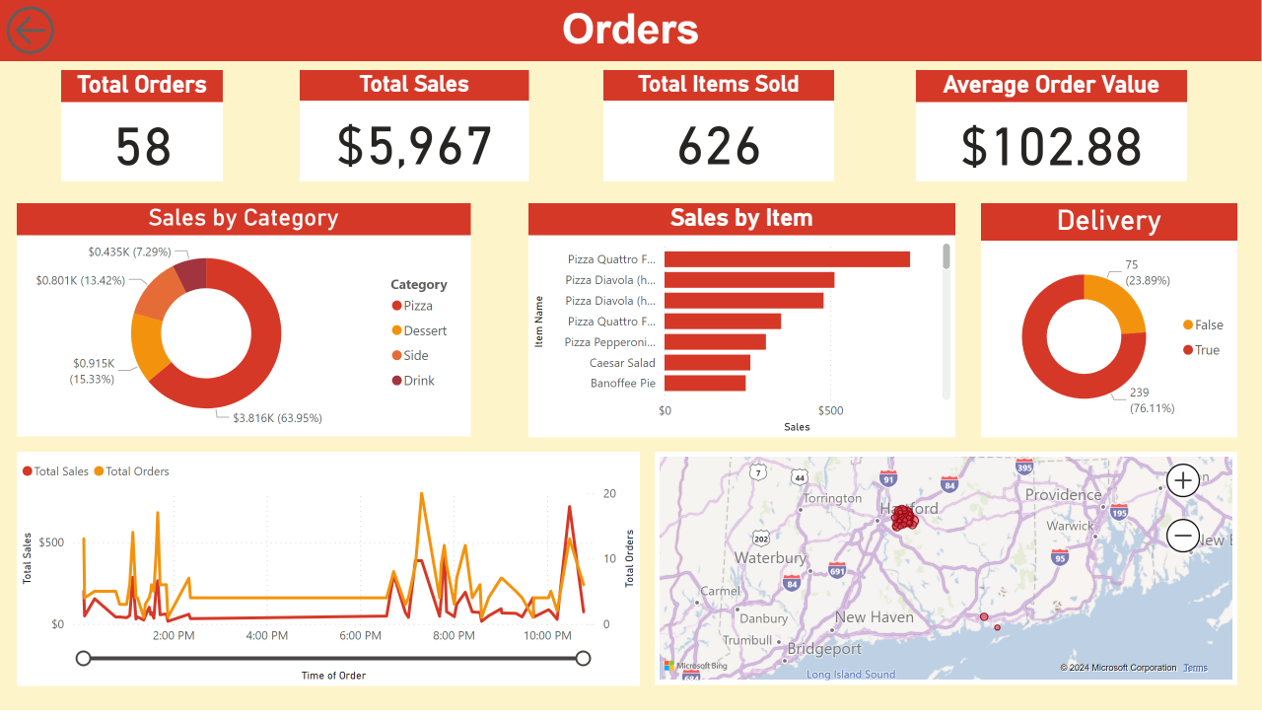

Order Activity Dashboard

- Sales trends

- Popular items

- Peak ordering times

- Delivery vs. pickup analysis

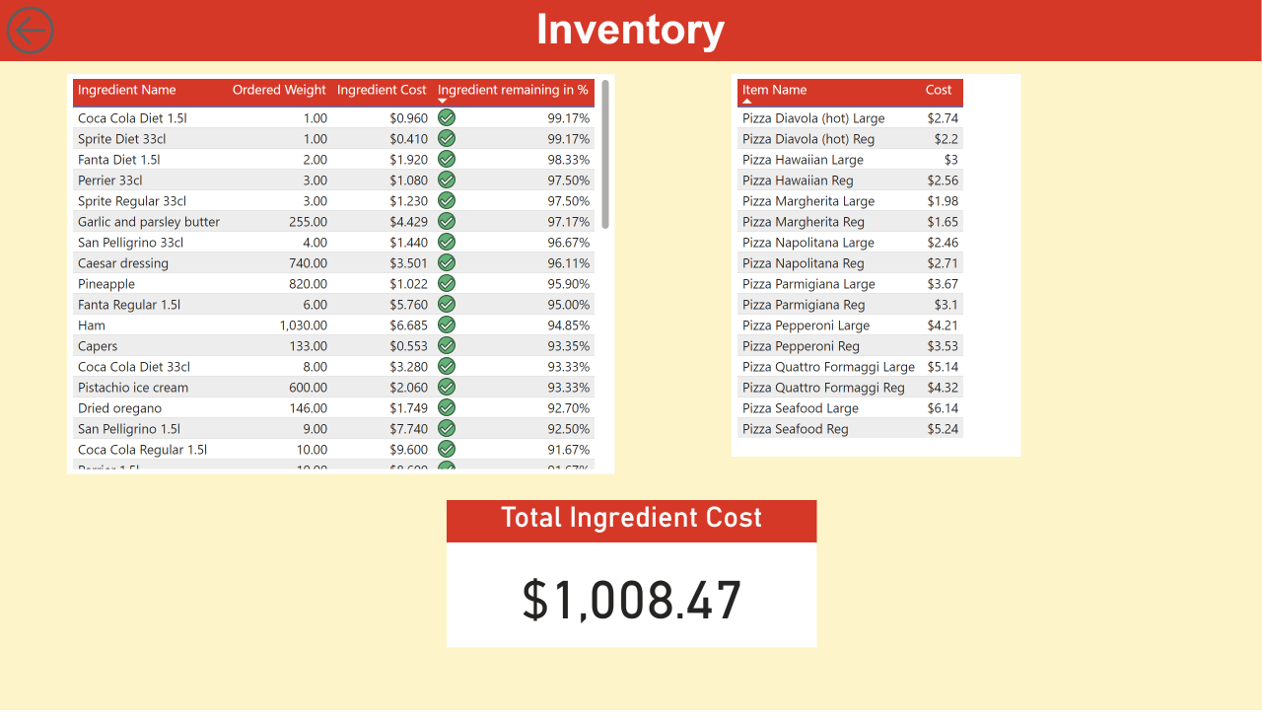

Inventory Management Dashboard

- Stock levels

- Ingredient usage

- Reorder points

- Cost analysis

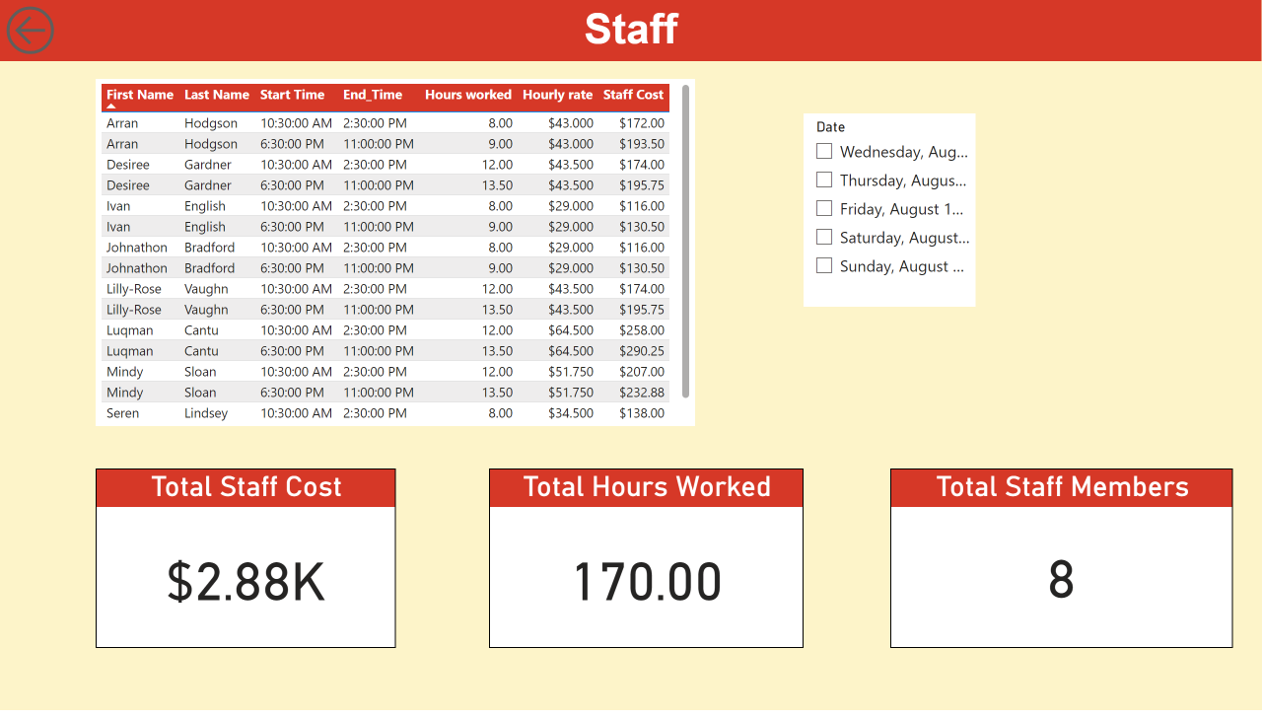

Staff Management Dashboard

- Labor costs

- Shift coverage

- Peak staffing needs

- Employee efficiency metrics

Analysis & Discovery

Analysis of the data revealed several key insights:

Sales Patterns

- Peak ordering times identified between 5-8 PM

- Higher delivery orders on weekends

- Most popular items are specialty pizzas

Inventory Management

- Several ingredients consistently running low before reorder

- Some ingredients overstocked relative to usage

- Seasonal variation in ingredient usage

Staff Optimization

- Current staffing levels misaligned with peak hours

- Overlap in shift schedules causing inefficiency

- Training needs identified in high-turnover positions

Recommendations

- Inventory Optimization

- Implement automated reordering system

- Adjust stock levels based on usage patterns

- Review supplier contracts for high-use ingredients

- Staff Scheduling

- Realign shift schedules with peak hours

- Reduce shift overlap periods

- Implement cross-training program

- Menu Engineering

- Focus promotion on high-margin items

- Adjust pricing based on ingredient costs

- Streamline menu options during peak hours

Implementation Plan

Phase 1: Database Implementation (Weeks 1-2)

- Set up SQL database

- Migrate existing data

- Test data integrity

Phase 2: Dashboard Deployment (Weeks 3-4)

- Build interactive dashboards

- Train staff on dashboard usage

- Implement feedback loop

Phase 3: Process Optimization (Weeks 5-8)

- Roll out new inventory system

- Update staffing schedules

- Monitor and adjust based on metrics

Success Metrics

- 15% reduction in ingredient waste

- 10% improvement in labor cost efficiency

- 20% faster order processing time

- 95% in-stock rate for key ingredients

This project demonstrates the power of data-driven decision making in restaurant operations, providing a foundation for continued optimization and growth.